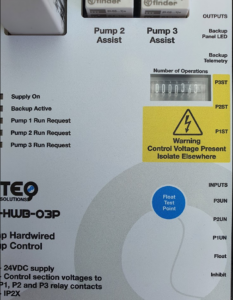

A 2 or 3 Pump Hardwired Backup Controller

A traditional hardwired backup circuit designed to reliably run up to a 3 pump pumping station in the event of the wet well primary control failure. Enables easy retrofit to existing panels through efficient space optimisation whilst maintaining use of standard easily obtainable components.

Benefits:

- Very compact: Up to 5 times smaller than the competition. Enclosure fits inside most MCC Control sections.

- Reliable operation: Uses highly reliable and proven components

- Ease of maintenance: Minimal maintenance required, but simple to maintain through plug in replaceable relays and timers.

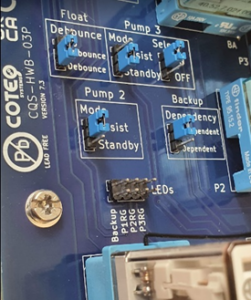

- Highly configurable: Functions covering a large number of pumping station types and control methods

- Simple to install: Simple connectors for all I/O and power

- Minimal training required: Consistent backup operation across all sites

Highlights:

- Very reliable, standard relay and timer components

- Float activated hardwired backup (direct or debounce timer selectable)

- Local indication of backup and pump status

- Fully independent hardwired backup with a simple ‘jumper’ option to enable a backup inhibit (i.e. if primary control is still healthy then the ultrasonic failed may be used to inhibit hardwired backup protection) – ‘Jumper’ position set during commissioning

- Isolated relay contacts for pump outputs (increased PCB track width to accommodate higher voltages) This removes the need for further interposing relays within pump start compartments / panels (‘Finder’ relays with 8A contacts used)

- 24V DC

- Efficient use of space for the timers and relays leading to a very small footprint to enable installation within existing control compartment (enclosure dimensions (including timer protrusion): 200mm x 120mm x 110mm)

- No need for glanding / terminations: Simple connectors leading in/out of the enclosure for input signals, pump run outputs and Power input.

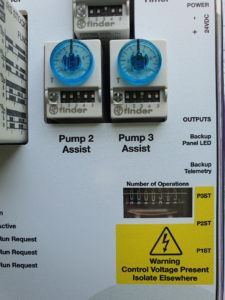

- Separate debounce timer, pump assist timers (for pumps 2 and 3)

- Run on timer to continue pumping after float level returns to normal

- Very simple installation and commissioning requirements: easy integration with existing panels

- Number of operations counter for predictive maintenance and indication of Primary control issues

3 Pump Hardwired Backup

Hardwired Backup Automatic Test Module

3 Pump Hardwired Backup

A 2 or 3 Pump Hardwired Backup Controller

A traditional hardwired backup circuit designed to reliably run up to a 3 pump pumping station in the event of the wet well primary control failure. Enables easy retrofit to existing panels through efficient space optimisation whilst maintaining use of standard easily obtainable components.

Benefits:

- Very compact: Up to 5 times smaller than the competition. Enclosure fits inside most MCC Control sections.

- Reliable operation: Uses highly reliable and proven components

- Ease of maintenance: Minimal maintenance required, but simple to maintain through plug in replaceable relays and timers.

- Highly configurable: Functions covering a large number of pumping station types and control methods

- Simple to install: Simple connectors for all I/O and power

- Minimal training required: Consistent backup operation across all sites

Highlights:

- Very reliable, standard relay and timer components

- Float activated hardwired backup (direct or debounce timer selectable)

- Local indication of backup and pump status

- Fully independent hardwired backup with a simple ‘jumper’ option to enable a backup inhibit (i.e. if primary control is still healthy then the ultrasonic failed may be used to inhibit hardwired backup protection) – ‘Jumper’ position set during commissioning

- Isolated relay contacts for pump outputs (increased PCB track width to accommodate higher voltages) This removes the need for further interposing relays within pump start compartments / panels (‘Finder’ relays with 8A contacts used)

- 24V DC

- Efficient use of space for the timers and relays leading to a very small footprint to enable installation within existing control compartment (enclosure dimensions (including timer protrusion): 200mm x 120mm x 110mm)

- No need for glanding / terminations: Simple connectors leading in/out of the enclosure for input signals, pump run outputs and Power input.

- Separate debounce timer, pump assist timers (for pumps 2 and 3)

- Run on timer to continue pumping after float level returns to normal

- Very simple installation and commissioning requirements: easy integration with existing panels

- Number of operations counter for predictive maintenance and indication of Primary control issues

Hardwired Backup Automatic Test Module

Coteq Solutions’ Automatic Test Module is a ‘Secondary control system health check monitoring device’ for small pumping stations, providing assurance that hardwired backup systems will initiate in the event of primary systems failure.

A Pumping station often has two levels of control:

- A primary control system that controls the pumps. (often on level with duty regimes).

- A secondary ‘hardwired backup circuit’ which is designed to run if the primary control fails.

Hardwired backup systems can remain idle for prolonged periods. Without regular monitoring, there is a risk the backup circuit will not operate when required, which leads to the potential of pollution events.

The CQS-HWB-ATM, Automatic Test Module, is designed to test the hardwired backup cycle at regular intervals, providing confidence that it will operate when required, and doing so without switching from primary control.

The Automatic Test Module can easily be integrated into most existing hardwired backup circuits and is a simple retrofit due to its compact size and straightforward integration into existing panels.

Benefits:

- Minimises Pollution risk: By regularly testing the backup circuits, the risk of pollution events on site are lowered significantly.

- Reduces need to attend site: Automatic testing and the additional function to remotely test the hardwired backup, reduces need for on-site checks of the operation of the Hardwired backup circuits.

- Test times optimised: The times at which the Testing is run can be controlled to fall within working hours, minimising any call out costs for faulty hardwired backup resolution works required

- Minimises the health and safety risk of float switch manipulation: Due to the automatic function of regularly running the backup systems, the need to undertake site manipulation of float switches (requiring access to wet well hatches etc) is reduced significantly.

- Clear visibility on the ‘health’ of every pumping station backup: Consistent backup testing functions across all sites promptly reports any issues.

- Very compact: 120mm x 120mm x 95mm (Footprint is not much larger than a fused spur enclosure). Fits inside most existing MCC Control sections

- Simple to install: Simple connectors for all I/O and power.

Highlights:

- Integrates into existing hardwired backup systems.

- Enables hardwired backup circuits to be exercised regularly, ensuring backup circuits are available in the event of primary control failure.

- Extremely compact; fits into most existing MCC control sections.

- Provides test result as inputs into SCADA (Test OK and Test Failed)

- 24V DC.